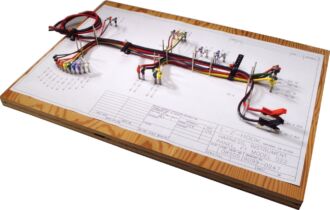

Is low pressure moulding a good alternative to traditional potting techniques when encapsulating electronics?

Low pressure moulding (LPM) is emerging as a compelling alternative to traditional potting techniques for encapsulating electronics. As a manufacturer deeply invested in the advancement of electronic component protection, we recognise the distinct advantages that LPM offers, which can significantly enhance the manufacturing process and the quality of the final product.