Posted on October 10, 2019

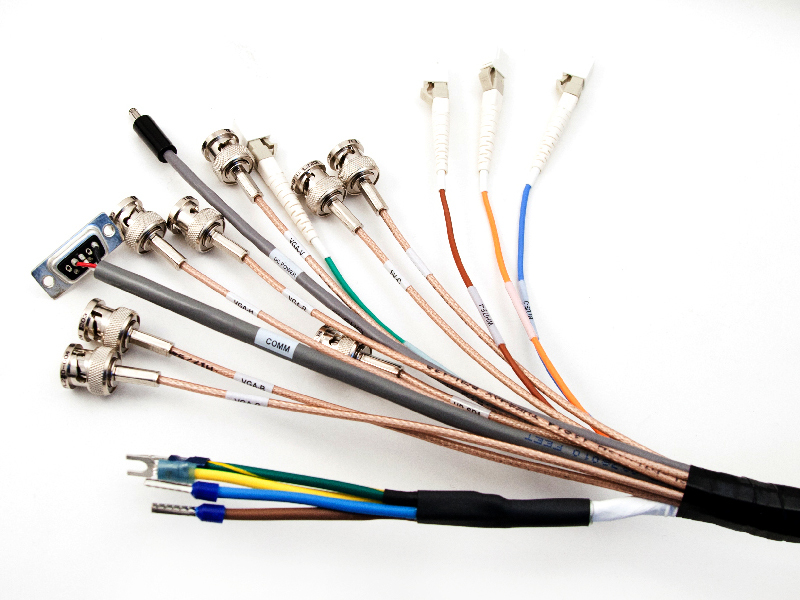

Why Choose IPC WHMA-A-620 qualified suppliers for your cable harness needs?

What is the IPC/WHMA-A-620 Standard?

The IPC/WHMA-A-620 Standard Revision C remains the only industry-consensus standard covering the assembly requirements and acceptance criteria of Cable and Wire Harness Assemblies.

The IPC/WHMA-A-620 standard prescribes practices and requirements for the manufacture of cable, wire and harness assemblies. The standard describes materials, methods, tests and acceptability criteria for producing crimped, mechanically secured and soldered interconnections, and the related assembly activities with cable and harness assemblies. Any method that produces an assembly conforming to the acceptability requirements described in this standard may be used.

The IPC/WHMA-A-620 standard sets expectations between WHMA members and their customers for what is considered acceptable quality workmanship for cables and harnesses. Use of the IPC/WHMA-A-620 standard requires agreement on the Class to which the product belongs. The User has the ultimate responsibility for identifying the Class to which the assembly is evaluated. If the User does not establish and document the acceptance Class, the Manufacturer may do so. It is an important piece to the process, materials, and inspections standard for the cable and wire harness industry.

This class based system also allows the standard to be used across a number of different industries – Class 3 products being military or aviation standard, Class 2 high level industrial product etc. this allows user of lower cost assemblies to still have confidence in the products supplied, without paying for quality at a level that is inappropriate for their product type.

Electronic Product Classifications:

Class 1: General

Includes products suitable for applications where the major requirement is the function of the completed assembly.

i.e., Everyday Consumer Appliances

Class 2: Dedicated Service

Includes products where continued performance and extended life is required, and for which uninterrupted service is desired but not critical. Typically, the end-use environment would not cause failures.

i.e., Televisions, Game Systems, Home Computing and Telephones

Class 3: High Performance/Harsh Environment

Includes products where continued performance or performance-on-demand is critical, equipment downtime cannot be tolerated, end-use environment may be uncommonly harsh, and the equipment must function when required, such as life support systems and other critical systems.

i.e., Medical Device, Military, and anywhere high performance is needed

The IPC/WHMA-A-620 Revision C provides the electronics industry with the most current criteria for the performance and acceptance of cable and wire harness assemblies. This revision includes a synergy with IPC-A-610 and IPC-J-STD-001, aligning many of the requirements that are in common with IPC/WHMA-A-620.

Included in the 19 chapters are criteria on safety wires and prep, requirements for individual wire seals, soldering to terminals, crimping of stamped and formed contacts and machined contacts, insulation displacement connectors, ultrasonic welding, splicing, connectors, connector molding, marking, coax/biax cables, raceways, grommets, wrapping/lacing, shielding, assembly and wire-wrap terminations. Over 428 pages. Released January 2017.

Have confidence in the supplier you choose for your assemblies – and choose a supplier with IPC/WHMA capability. Please do not hesitate to contact Greenstock for more details.