Posted on August 28, 2019

When designing a new product, engineers focus mainly on functionality, features, styling and cost. What they don’t always think about is the wiring. Unfortunately, that’s often forgotten about until the last minute. At Greenstock we often see design compromises being made, or additional unintended costs being incurred as a result of poor wire harness design or lack of forward planning in this area.

Engineers need to put more thought into things like wire length, bending radius and routing. As wiring harnesses become increasingly complex, that type of forward-thinking is more important than ever.

“Engineers are trying to do more in tighter bundles with different types of wiring, such as combining high speed with power, all in one raceway or cable,” says John Kuster, senior product manager for harness components at TE Connectivity. “Complexity is introduced in adding the need to protect each type from its neighbor’s electromagnetic or radio frequency interference, let alone the outside influence of the environment.”

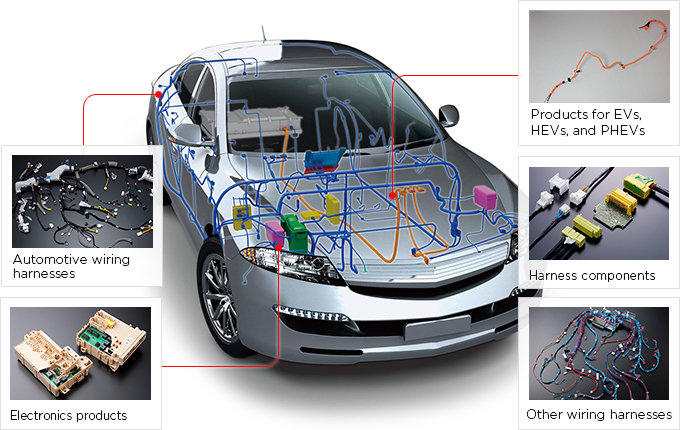

“If you take a car, for example, there are many more computers and electronic control units used in vehicles today than just a few years ago,” adds Geoff Lydon, E3 series solutions manager at Zuken USA Inc., a supplier of design software. “These ECUs are used to control the transmission, and the operation of windows, doors and other devices.

“But, as new convenience options have been added, such as automatic tail gates and lane-departure warning systems, they have required additional ECUs,” says Lydon. “Each of these ECUs use data from sensors positioned throughout the vehicle and they have to be connected via wire harnesses in order for the systems to work.”

When designing wire harnesses, engineers tend to make several mistakes, ranging from mismatching wire capabilities, such as bend radius, temperature rating and chemical resistance, to losing sight of the complete system.

“One of the worst mistakes [people make] is cutting the wires too short, as this tends to scrap the whole harness,” says Jon Collins, business development director at design software firm Cadonix Ltd. “Another common mistake is not carrying through the initial design intent as far as the connectivity definition is concerned.

“This is a particular issue when there is no automatic integration between the schematic diagram and the harness layout and manufacturing tools,” explains Collins. “This generally shows itself when manual methods are used, such as using Visio for drawing and Excel for connectivity listing. A totally manual process tends to introduce human errors, which in turn leads to unscheduled rework of the harness and has a knock-on effect to delay the next project.”

“The biggest mistake that engineers make when designing wire harnesses is failure to control and translate the preliminary, functional, analytical and commercial requirements of the harness system into efficiently connected product lifecycle management methodologies and workflows,” claims David Roach, business sales manager for Harness proD at EPLAN Software & Services LLC.

“These include not only those elements of design, but also economies of scale related to manufacturability, mass production, product variation and consumer demand,” adds Roach. “An example is the harness design that meets all of the preliminary design requirements, but offers no availability for design change, due to custom or proprietary component use, or labor-intensive operations not taken into consideration.”

Another mistake that engineers make is lack of standardization in the design criterion. “Electrical harness designs that are based on adaptation to physical prototypes often involve [engineers] physically measuring wire lengths and determining routing paths using flexible cord or string, and the subsequent accumulation of handwritten data,” Roach points out.

“These types of methodologies rely on visual inspection of the first harness produced, as well as an iterative design cycle of modifications due to physical environment revisions to which the wire harness must function,” says Roach. “Studies have long proven that visual inspection has a false positive rate of approximately 2 percent and a false negative rate of 23 percent.

“These statistics often prove expensive when applied to manufacturing and design processes, and result in appreciable financial costs,” warns Roach. “Standardization of the work and data flow is crucial to avoiding costly mistakes.”

Follow the Route

No matter what type of product is being assembled, engineers must ensure that wiring harnesses are routed correctly. According to Roach, the best way to do that is to accurately analyze the complete physical environment in which the harness must function. “Sharp edges, thermal changes of surface conditions, electrical magnetic interference's and moving parts are examples of environmental conditions that can affect the correct routing of wire and cable harnesses,” he points out.

Kuster recommends providing adequate “free space” for the bundles; providing adequate protection of the cables during routing, such as lining cut-outs and having appropriate glands or feed troughs; protecting against chaffing; and providing adequate clamping or fixturing support.

Typically, physical mockups are the best way to ensure correct wire harness routing. But, they can be time consuming and expensive. With the recent proliferation of 3D mechanical design software, it has become much easier, faster and cost-effective to create a virtual prototype by routing harnesses within a CAD model of the product that is being designed, especially if the software’s routing functionality is used.

“These routing tools not only provide the means to route cables and harnesses, but also utilize the true overall diameters of wires and cable bundles, and indicate when bend radii have been exceeded,” says Lydon. “This allows adjustments to be made within the 3D world before any harness is actually built.”

“[However], it is essential that the correct connectivity data is passed through to the 3D routing tool from the schematic or wiring diagram,” adds Collins. “So, the interfaces between the 2D logical world and the 3D physical need to be well integrated.

“Although this is one of the safest methods, [few engineers] actually use this,” claims Collins. “Creating the 3D models for connectors is time-consuming. Using the routing tools can be complicated, because you need to be a proficient user of the mechanical tools that the routing tools depend on.”

Another mistake that engineers make when designing wiring harnesses is not ensuring that all the wires will be long enough to accommodate various bends and turns.

Roach suggests carefully considering the physical environment. “Having access to a virtual model of the environment, as well as a tool that will return wire lengths and allow the designer to test the routing, will ensure that engineers will have sufficient resources to successfully route a harness in accommodation of even the most complex bends and turns,” he points out.

“[Another option is to] prepare one end so [assemblers] only route in one direction,” says Kuster. “That means you need to estimate long, and expect to have to cut and terminate one end on-site. You can never completely understand the route a cable will have to take. Estimate long, then route and cut or terminate to suit the need.”

Greenstock can aid in the harness design process, producing prototype products to aid engineers through the test processes and advising on the best connector, wire products to use given specific environmental considerations. We can translate this design & engineering work into full volume manufacturing to support ongoing demand. For more information please contact our sales department on 01522 522522.